The rapid advances in sensing, battery, and aeronautics technologies, together with autonomous navigation methods and equipped low-cost digital cameras have helped make UAVs more affordable, reliable, and easy to operate. Today, large numbers of Architecture/Engineering/Construction and Facility Management (AEC/FM) firms and relevant service companies use these platforms to visually monitor construction and operation of buildings, bridges, and other types of civil infrastructure systems.

Standard Railway Gauge- Kenya

Hydropower Dam

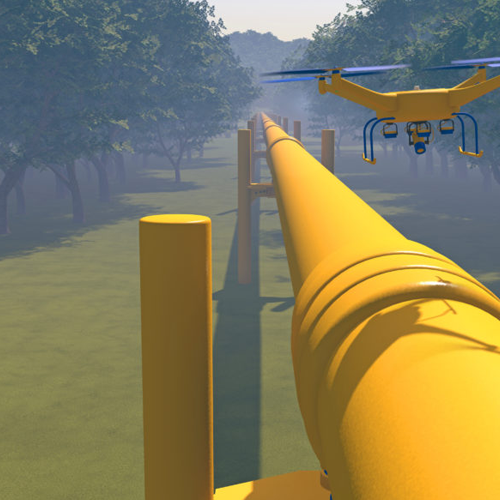

Pipeline Inspections

ENERGY AND UTILITY

The potential of drones to assist in maintaining power & utilities networks is even greater. Maintenance of assets spread across a vast area, accessing hard-to-reach infrastructure and execution of dangerous inspection procedures normally performed by humans, or by expensive helicopter or airplanes, can all be replaced by drones. UAVs beat other technologies by making inspections cheaper, faster and safer.

Wind Turbine Inspections

Our drones provide the aerial platform for close range viewing and recording, for the purpose of determining present conditions, and/or for documentation of completed repairs and inspections of wind turbine blades and shafts.

This is a role that has traditionally been accomplished from the ground with simple visual inspections or more complicated and risky rope or platform access.

The drones not only have robust stability in strong winds, strong batterylife and sharp optics but also inegrate data analysis systems and softwares that can automate the data processing.

- Structural integrity inspection of turbine blades for damage, corrosion, cracks and erosion.

- Condition monitoring of the wind turbines.

Solar Panel Inspections

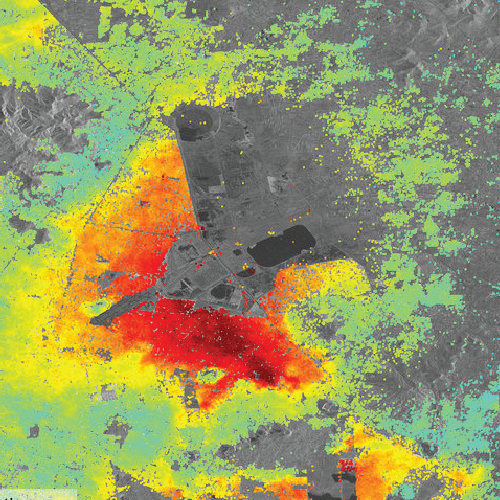

Our drones can be flown autonomously over solar fields using pre-programmed GPS waypoints. This enables the capture of both visual and thermal infra-red imagery, allowing the identification of hot spots, glass cracks and shading. This increases the inspection rate which eventually leds to increase in production output of the solar panels.

- Visual and thermal (infra-red) imaging, for identification of hot spots, glass cracks, shading and decrease in solar cells efficiency.

- Solar panel cleaning.

- Initial mapping of a proposed solar farm location for illumination optimization

Power and Utilities

Flying above potentially damaged utility lines and high vertical structures, such as telecommunication masts, in order to take accurate and clear aerial pictures and videos for inspection.

- Analyzing structural integrity and assessing damage to critical components. Providing visual information on equipment (insulator status, tower and pole conditions).

- Wear and tear by corrosion. These power cables are open so due to wet weather the metal cables may get corrosion which may cause power waste.

- Damage by animals and birds.

- Thermal profiles of conductor and splices.

- Vegetation and other potential right-of-way incursions.

- Concrete degradation and other abnormal conditions.

OIL AND GAS

The oil and gas industry is increasingly relying on robots like unmanned aerial vehicles for inspection. These drones can get into hard-to-reach or hazardous spots. They do not get bored. They can measure with precision. And they can save significant amounts of time.Inspecting equipment at height, such as flares and cooling towers, or under the deck typically requires personnel to use ropes for access. Setting that up takes time, and the work itself can be hazardous. Enter the drone, which requires little set-up time.

Freight and Cargo Logistics

Oil Field Mapping and Exploration

- Fast and accurate acquisition of aerial images of production sites.

- Geological mapping and survey.

- Oil Prospecting.

Power and Utilities

- Inspection of oil rigs, storage tank and oil field infrastructure.

- Flare stack inspections.

- Elevated structure inspection for wear, corrosion and damages.

Supply Chain

- Monitoring the supply chain of crude oil by road/rail.

Emergency Response

- Aerial informaion on oil leaks and spills.

- Emergency response in case of accidents.

- Safety enhancement and evacuation.

Aerial Surveillance

- Accident and damage assessment.

- Disaster response.

MINING

Unmanned aerial vehicles (UAVs) have recently gained popularity in the geosciences because they can be used for the systematic acquisition of georeferenced, high-resolution aerial photographs at relatively low cost, over large surface areas (hundreds of metres to kilometres). Such a workflow permits the extraction of spatial information from a series of overlapping photographs based on computer vision algorithms. The resulting computed 3D photorealistic models can provide digital elevation data and be used to accurately measure large amounts of spatial data in a fraction of time compared to traditional geological workflows.

STOCK PILE INVENTORY MANAGEMENT

MAPPING OF STEEP INACCESSIBLE INCLINES

SAFETY AND COMPLIANCE MONITORING

PRE- AND POST-BLAST DATA ACQUISITION

WATERSHED, DRAINAGE BASIN & WATER FLOW MAPPING

PROJECT FEASIBILITY STUDIES

PROJECT PROGRESS MONITORING & REPORTING